patconvalves@gmail.com

The COMPACT VALVE TESTER VERIFIER has been designed and developed for checking the sensitivity of COMPACT VALVE TESTER to detect a rate of leakage of the order of 0.5gm/hr

COMPACT VALVE TESTER the instrument is highly sensitive and can detect the leakage of LPG up to 0.5 gm/hr within 3sec. Of time.

The instrument is designed to check both the possible leakage regarding the SC valve fitted on Domestic LPG cylinder. The probable leakages are:

The leakage of LPG from the spindle of valve and the probable leakage through the joint seal fitted in between the SC valve and regulator, after the fittment of regulator.

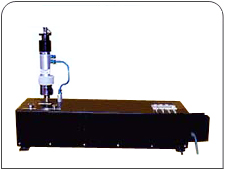

AUTOMATION FOR MECHANICAL WEIGH SCALE

It is the automation of mechanical weigh scale achieved pneumatically. The operator has to place the empty LPG cylinder on the weigh scales, set the required gross weight, lower the hung pneumatic filling head on the valve, and press the pneumatic valve to give the 'ON' signal to the system. The system will automatically stop the filling of LPG and release the filling head after the preset weight is filled.

CVT SYSTEM system is designed to test the Sc valves fitted on domestic LPG cylinder after filling. The system is designed to detect the leak on-line.

The system stop/holds the first incoming cylinder on conveyor. The operator then lowers the CVT on the SC valve and press the pneumatic foot valve. After preset time the system will automatically declamp and release the CVT. The system will then release the tested LPG cylinder and the cycle will be repeated for next incoming LPG cylinder.

AUTO-HEAT SEALING SYSTEM

System is designed to heat seal the PVC - seals on the domestic cylinder valves, on-line. The system is totally pneumatic and automatic. The system is installed along the side of the conveyor. The first incoming cylinder is sensed and hold by the system.

The steam cup starts moving down, while the LPG cylinder is still moving, overlapping the horizontal movement of LPG cylinder before it stops.

The steam valve gets opened as the steam cup senses the top of the LPG cylinder and the entire assembly of steam cup, steam valve retracts. The LPG cylinder is released. The system is now ready to heat seal the next incoming cylinder.

The capacity of the system is to heat seal about 1,200 cylinders per hour

The equipment is designed and developed for testing the SC VALVES & DOMESTIC LPG regulators as per IS:8737 1995 & IS:9798: 1995 respectively.

The equipment is designed to conduct low pressure tests at900mm, 1000mm & 1500mm water column test pressure and high pressure of 17 kg/sq.cm. The equipment can also be used as production test bench to test the SC VALVES as per IS : 8737 :1995